|

Getting your Trinity Audio player ready...

|

Manufacturing has always been defined by precision, performance, and progress, but the industry has changed today. Digital Twin Development is going to change how factories will operate, products will be designed, and efficiency will be achieved in the time to come. It is no longer just machinery on the floor; it is about how machines communicate, learn, and predict.

An almost breathing, living, real-time digital representation of the system, process, or physical asset is called a digital twin—an embodiment of reality. These virtual models link the industry with real-time data analysis through IoT sensors and AI intelligence, ranging from a single robot performance monitoring to the entire factory efficiency analysis. Digital twin technology brings a data-based analysis at every phase of manufacturing.

Such really might touch an exciting change in years ahead, very much by the integration of AI, IoT, and cloud-based, digital-twin market platforms. Manufacturers can connect all equipment, systems, and data in a real-time environment to ensure and predict failures before their occurrence, run the designs virtually, optimize energy consumption, and improve total production efficacy. It is this bridge between physical operations and intelligent automation where insight meets action.

It is a necessity for the companies that are interested in being ahead for the Industry 4.0 revolution to embrace digital twins. They transform the way decisions are made, turning guesses into foresight and downtime into continuous improvement.

Esferasoft operates at the beta stage of digital twin development services to help manufacturers transgress into more intelligent, safer, and more efficient operations. Such capability in IoT integration, analytics of AI, and virtual replica technology guarantees that the business has opened a channel through which every physical asset can be exploited optimally via an intelligent, connected system.

What is a digital twin?

A digital twin is a dynamic, virtual replica of a physical object, system, or process, designed to mimic the behaviors of its ‘real’ counterpart. Digital twins differ from a static 3-dimensional model or a one-off simulation by constantly being fed with real-time data from sensors, IoT devices, or connected software platforms. This constant data flow allows the twin to ‘live and evolve’ alongside its physical counterpart with respect to changes, performance predictions, or suggestions for improvement.

In manufacturing, a digital twin may represent anything from a single machine to a whole production line or facility. Digital twins provide engineers and decision-makers with a 360° digital view of operations , thus helping them understand how assets perform under various conditions without physically testing or disrupting them.

Difference between a Digital Twin and Simulation and Traditional Modeling

Many people believe that virtual twins are nothing more than sophisticated forms of simulation. There is, however, a principle that separates the two: namely, connectivity and instantaneous feedback.

- Traditional modeling provides a visual and mathematical representation of a system all at once, but once completed, it remains static.

- Also, with simulation, it allows a test of scenario but still it depends on preset data entry inputs.

- Digital twin technology, however, works continuously, using real-time IoT data and AI driven analytics to keep the system monitored for performance, forecasting of outcomes, and recommending changes automatically.

To put it differently, simulations are snapshots, while digital twins are live video feeds of your manufacturing ecosystem.

Core Elements of a Digital Twin

A digital twinning system requires several components to work together to perform optimally:

- IoT Sensors & Devices: To harness data from machinery as well as the environment and the entire operational system.

- Data Integration Layer: This refers to connecting the devices to the digital model so that it receives data seamlessly.

- Cloud Infrastructure: When it comes to real-time handling and storage of extremely large amounts of data, this should allow for the scaling and, especially, remote access.

- Analytics Dashboard: This is about performance metrics, warning forecasts, and insight simulation.

- AI and Machine Learning Models: It takes the pattern of data and draws possible futures that can occur before instances where they actually happen.

In this way, the entire operation operates under a continuous digital feedback loop that increases the accuracy and responsiveness of the entire organization.

Magic of Continuous Feedback

The entire magic here is two-way in approach. Data flows from the physical system into the digital model, analyzes, and provides actionable insights, and those insights can be implemented back into the physical environment to continue this cycle of turning reactive processes into proactive intelligence.

Imagine a production line that would adjust its temperature or speed or would adjust its power supply automatically based on the predictions and wear of demands.

Digital twin technology thus promises to turn static machines into intelligent self-optimizing systems linked by a physical-signaling bridge.

The physical and digital worlds are connected by digital twins, which allow manufacturers to attain unprecedented levels of accuracy, decreased expenses, and resilience.

How Digital Twin Development Takes Place in the Industry

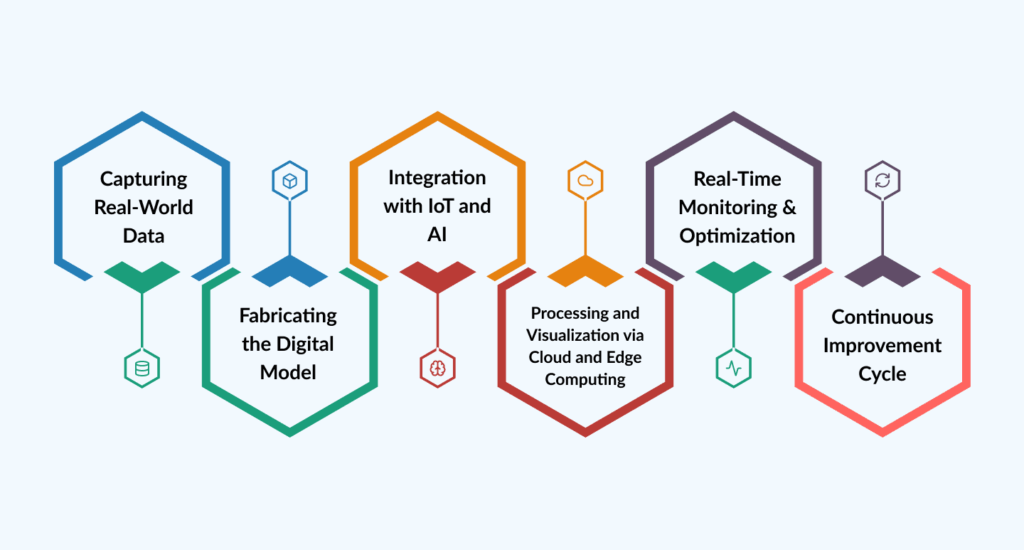

Step 1: Capturing Real-World Data

Foundation to every digital twin development process is data collection. Manufacturers install IoT sensors and smart devices along machinery, production lines, and floors of manufacturing to collect parameters such as temperature, vibrations, pressure, and speed. Such sensors will stream their information continuously to the cloud, creating the raw data layer upon which the digital twin operates.

Access to this live feed renders a transparent view for all factories regarding the manner in which all the machines and operations behave under real conditions in the real world. This is where the physical world first begins to interface with its digital representation.

Step 2: Fabricating the Digital Model

Once data collection is finished, developers and engineers make a virtual version, which will reflect the physical system. The construction of the model will require aligning the definitions of CAD models, process workflows, and historical performance data in the software specifically designed for the digital twin. By using technological replicants, the digital twin simulates what happens when either machines or systems run—from motion at the production line up to material flow.

Thus, this mode clearly defines how well-tuned the twin is regarding the prediction and optimization of outcomes in real-time.

Step 3: Integration with IoT and AI

The real strength of digital-twin development lies in the integrated environments of IoT and AI. The former brings on data streams that feed odometrically, whereas the latter runs all kinds of algorithms on the digital twin using AI interpretation of the captured data to detect anomalies, forecast issues and trigger responses.

For instance, when an increase in vibration levels from a machine goes above limit, the digital twin then flags that potential maintenance issue before it escalates to the breakdown. Also, hundreds of “what-if” scenarios can be tested by the AI models to determine the most efficient production setup, with all the best things done without ever halting real operations.

Step 4: Processing and Visualization via Cloud and Edge Computing

The amount of data collected from machines is normally so vast that it won’t be able to be handled by any of the traditional processes. This is why cloud-based digital twin platforms and edge computing play important roles.

- Cloud computing enables vast amounts of data storage over distance and thus allows collaboration among users of the system while being scalable.

- Edge computing brings computation nearer to the actual devices. This further lowers latency and allows for near-instantaneous responses in critical environments.

This combination helps ensure that digital twins not only analyze data but also respond in real-time—whether it is adjusting a robotic arm’s motion or rebalancing production loads.

Step 5: Real-Time Monitoring and Optimization

After being operational, the real-time digital twin will monitor factory activities and analyze factory activities continuously. From an interactive dashboard, engineers can visualize the performance metrics, test out changes virtually, and make data-driven changes right away. Actualizing this live loop of observation, simulation, and improvement would take factories out of reactive maintenance into predictive and prescriptive optimization, saving time, cost, and energy.

Step 6: Continuous Improvement Cycle

Digital twins do not just stop at monitoring. Every insight it generates feeds into refining the twin itself, making it pick up intelligence over time. Every moment, with continuous streams of data, machine learning models improve on their previous predictions, adapting the system to changing conditions, production targets, or new technologies.

The digital twin, in short, changes manufacturing into intelligent and self-learning ecosystems wherein decisions are nearly always right, and every process is continuously moving toward its efficacy frontier.

Most Use Cases of Digital Twins within Manufacturing

Digital twins are not an innovation but share substantial differences from the current state of manufacturing systems. Making use of IoT data, AI, and real-time simulation, digital twins turn into the brain between physical operations and intelligent optimization. These are some of the strongest and most proven applications of digital twin technology in the manufacturing sector.

Predictive Maintenance

This was probably the earliest application of digital twin technology, but also one of the most valuable.

Instead of the usual after-the-fact reaction to breaking down, manufacturers can see when failures are upcoming.

By using IoT, digital twins can monitor and analyze parameters like vibration, temperature, and power consumption to separate the symptoms of initial failures.

For example, when the twin predicts that a bearing might fail within the next few weeks, maintenance may be arranged during scheduled downtime—potentially saving the cost of disruption.

Such an approach applies equally to predicting deterioration with regard to cost of repair and delay in production. The result is optimal efficiency operating at the highest levels.

Production Optimization

Even a minor inefficiency today contributes to serious disruption to productivity. The concept of a digital twin gives the manufacturer instant insight into the lines of production and the flows of processes.

For example, one could change the input materials or speed of a machine and then simulate it in order to locate the bottle and test improvement on the virtual platform before applying it in the real world.

It optimizes throughput, reduces waste, and balances workloads across the facility.

An AI-powered system will make manufacturing operations adaptive on the part of the PI implementation by learning from past data transferred to fine-tune future performance, making it both leaner and smarter.

Quality Management and Process Improvement

Quality of product differs consistently among production cycles—most of the time a headache for the manufacturing engineer. Digital twins operate akin to virtual quality inspectors, identifying anomalies in every possible way of production and verifying precision.

For example, if a product moves outside the variable tolerance level, it instantaneously recognizes that with its digital twin and recalibrates with an instant corrective measure.

That means fewer defects, greater traceability, and less use of materials. Usually over time, such informed decisions would lead to areas of process inefficiency in manufacturers, which means greater refinement and higher customer satisfaction.

Supply Chain Management

Supplying the globe’s factories and every part of the manufacturing network today becomes part of a ripple from the latest chain disruption affecting the entire manufacturing network.

Modeling supply chains by the use of digital twins enables manufacturers to test “what-if” situations such as shortages in raw materials, demand fluctuations, or some other plausible negative scenario to plan alternative routes or suppliers before a crisis strikes.

This visibility in the supply chain ensures agility, resilience, and optimized times of delivery, even in unpredictable conditions in markets.

Product Design and Prototyping

Digital twin models for testing new designs under varying conditions will allow manufacturers to virtually evaluate a new product concept before spending on real prototypes.

In the virtual environment, engineers can replace materials and stress levels and performance parameters relative to the application to achieve the optimal design without wasting time or materials.

This would reduce the length of R&D cycles, the costs of prototyping, and increase time to market. In this respect, artificial intelligence combined with data analytics integrated into the digital twin should suggest design improvements aligned to ultimate performance and sustainability goals.

In short, these digital twin solutions from us at +91 772-3000-038 would equip the manufacturers to gaze forward, into precision and flexibility while predictive maintenance, smart product design, and all that manufacturing may change into measurable, manageable, and future-ready.

Aspects of Employing Digital Twin Technology in Businesses

More than enhancing efficiency, digital twin technology offers specific business advantages as manufacturers move toward intelligent factory processes—factory systems capable of responding adaptively to real-time demands, used by machine-twin development in realizing tangible value throughout operations.

Reduced Maintenance and Operating Expenses

Shutdown time analysis has been done and proven that both methods of timing, reactive or scheduled maintenance are very expensive and inefficient. With the introduction of the digital twin monitoring systems, it becomes possible for manufacturers to change over completely to predictive maintenance, determining conditions that would lead to a failure of equipment before it happens.

While keeping a close watch on the data emanating from IoT in real time, the twin detects early operational failures, automatically triggering maintenance alerts. This all helps to minimize downtime and prolong the life of equipment while cutting repair costs; in large-scale systems, this can mean millions saved yearly.

Enhanced Productivity and Efficiency

A real-time digital twin constantly assesses machines in terms of their performance, flow of production and allocation of workforce. It also gives crucial information to identify bottlenecks, underperforming systems, or unnecessary energy use—enabling decision-makers to act fast.

This constant stream of insights empowers manufacturers to fine-tune processes, balance workloads, and enhance line performance. As a result, productivity improves not just incrementally, but systematically across the entire manufacturing ecosystem.

Improved Product Quality and Reduced Waste

Consistent production quality directly affects the name of the company and even profits. Precise standards ensured by the digital twin solutions can be in place throughout all manufacturing stages, from assembly through heating to materials used and quality checks.

Simulating “what-if” scenarios, manufacturers can test process changes without putting real production output at risk. Such data-driven controls will minimize rework and damaged production material and ensure more quality products get to the market.

Shortened Development Cycles and Acceleration of Innovations

In today’s competitive environment, timely decisions become extremely important activities. The digital twin can speed up innovation since R&D teams can develop, test, and optimize prototypes virtually rather than physically build one for testing.

It subsequently reduces costs on development stages while making the time to reach the market a very essential element of today’s fast-moving industry.

Data-Driven Decisions

One of the major advantages of industrial digital twins is that they can turn more complex data into actionable intelligence. Hence, from shop floor managers to the C Level suite executives, everyone has instant access to real-time analytics coupled with visualization dashboards that support evidence-based decision-making.

With insights born of AI, IoT, and cloud-based digital twin platforms, organizations match business strategy to operational realities that often narrow or completely bridge the gap between planning and performance. Thus, adopting digital twin development is not just a technological leap; it is a strategic investment in intelligent and sustainable manufacturing. Those who take the plunge early shall find themselves at the forefront of ushering in the next age of data-driven, autonomous, and resilient production.

Digital Twin Technology: Challenges in Adoption

Adoption of digital twin technology has the great promise to redefine the manufacturing sector but very often faces an uphill task. From high configuration costs to data security constraints, organizations have to integrate digital twins with strategic foresight and technical readiness. Here are some common impediments that manufacturers face while trying to mimic the upgrades in technology.

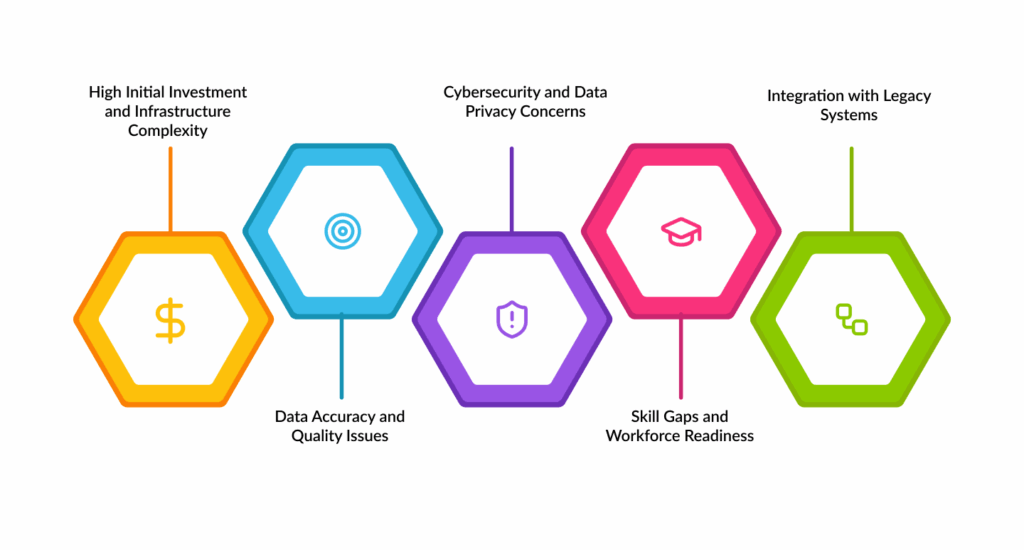

1. High Initial Investment and Infrastructure Complexity

Creating a fully functional digital twin ecosystem requires a strong IoT-enabled ecosystem with other integrated machines, cloud platforms, edge computing devices, and advanced analytics software systems. For a manufacturer, more so for small and medium enterprises, the initial investment can feel like a big barrier.

Furthermore, constructing the model for the digital twin itself requires skilled developers, engineers, and data scientists capable of integrating heterogeneous systems into a cohesive architecture. Without this expertise, the endeavor may become disjointed or worse—inefficient.

This hurdle, however, can be overcome with phased implementation, beginning with a pilot project for an asset or process, with expansion as measurable results indicate. Such an incremental approach minimizes risk over an extended time horizon to establish budgets within which to accrue costs.

2. Data Accuracy and Quality Issues

User assistance hinges practically entirely on data quality as labeling success. Erroneous simulation, bad prediction, and wrong decisions are results of inconsistent or incomplete data.

Proper calibration of sensors, reliability of pipelines, and maintaining common synchronization across machines and systems will ensure correct installation of the digital twin in manufacturing.

Even a small aberration, such as a temperature sensor slightly out of calibration, can dramatically impact the performance insight derived from the entire model.

This requires that manufacturers must commit their investments to an extensive data governance framework with real-time monitoring and periodical inspections to prevent having an unclean, inaccurate, and inconsistent data flow.

3. Cybersecurity and Data Privacy Concerns

Cybersecurity remains a major concern since digital twin software relies on real-time data exchanges over the IoT and cloud platforms. Each connected device and any gateway could serve as a potential entry point for malicious activities.

Unauthorized access to sensitive production data or digital twin models could lead to operational sabotage or theft of intellectual property. Working alongside cybersecurity experts from the early design phase of the digital twin in development also helps block out vulnerabilities before deployment.

4. Skill Gaps and Workforce Readiness

To build AI-based digital twins an array of skills is required, including those involving IoT architecture, data analytics, and industrial automation. Often, these are new technologies to many traditional manufacturing teams.

They may find it challenging to understand and interpret data from digital twin dashboards or to make appropriate changes at an operational level based on data without investing in upskilling through training.

Organizations can avoid this barrier by investing in continuous learning programs, workshops, and partnering with the organization’s digital transformation partner, Esferasoft, between technical development and operational guidance.

5. Integration with Legacy Systems

The majority of factories are still stuck on legacy systems and machines that do not possess IoT capabilities. Basically, the connection of these legacy systems to any digital twin platform turns out to be complicated and costly from a technical perspective.

Often, this requires retrofitting sensors or developing middleware to enable communications between the new digital twin software and the old industrial equipment.

A successful integration strategy involves gradual upgrading, starting with key assets generating the most operational data and progressively increasing connectivity across the plant.

No doubt, removing the operational hurdles presents challenges; for these challenges, solution paths exist that are paved with wisdom, partners, and a battle-tested strategy. With this help and smart planning, the digital twin development services of Esferasoft will transform these chain barriers into pillars for a smart, connected, and resilient production environment. Call now and learn more at +91 772-3000-038!

The Digital Twin World in Smart Manufacturing

The near future of the development of digital twins is hugely interconnected with the advancement in smart manufacturing and Industry 4.0. In future factories that are widely connected, intelligent, and automated, digital twins will become the brain of the operations—predicting, adapting, and optimizing production processes in real time.

Artificial Intelligence, Machine Learning and Edge Computing

Digital twins evolve into learning tools, no longer static but dynamic in their self-learning from AI and machine learning. These so-called intelligent twins observe the constant flow of production data and cite inefficiencies, predict future performance, and make self-operation adjustments.

The machine learning algorithms can compare thousands of data values from material flow to energy consumption. With that data, machine learning recommends efficient process parameters. With time, the twin becomes smarter and self-correcting, being able to adapt to changing production conditions.

Edge computing basically brings computation close to the sources of data—those machines themselves—and that results in immediate feedback and real-time responsiveness, making the electrical systems self-act when delays may affect output or safety.

Spearheading the Industry 4.0 Vision

It is through digital twins that the new manufacturing will most importantly gain access to the Industry 4.0 revolution. Manufacturers can then achieve an unprecedented level of agility and preciseness by creating interconnected systems of communication with each other.

In a smart factory, a digital twin enables real-time decision-making with each of the IoT sensors, robotics, and AI-harnessed automation. The aforementioned results bring an integrated ecosystem where each of those assets—from machines to supply chains—works in tandem.

It is the convergence of technologies that makes manufacturing smart but also resilient to change, with businesses adapting quickly to market fluctuations, resource shortages, or even design changes.

Predictive, Autonomous, and Self-Healing Systems

The newest abilities in the new age of digital twins are self-healing operations: detecting and fixing problems before they shut down production.

Imagine a factory where the digital twin knows a probable fault, runs simulations on how to fix the fault, and instructs the machine to do the fixing—without human intervention.

Such automation would portray a whole new definition of reliability, efficiency, and uptime.

Digital twin would take its evolution and integration with AI-based analytics and, increasingly, RPA systems within those venues to create a new definition of predictive system into prescriptive intelligence—it does not just predict outcomes but actually takes action to realize something more than just tangible gains.

Now Digitally Twin Modeling of Future

Focus is more on manufacturing operations currently, but the emerging future of digital twin technology is much broader than this.

Digital twins in R&D will be the ones testing thousands of prototypes virtually before physical production starts—fast-tracking product innovation.

At Esferasoft, we keep providing digital twin development services and we prepare manufacturers for the future, where transformation from data to intelligence will take place and leave factories as living learning ecosystems. The next era of manufacturing will not just be smart. It will be self-aware. Call now at +91 772-3000-038 to learn more.

Conclusion: Where the Material Meets the Intelligent

Manufacturing has gone beyond assembly lines and machinery; now it is heading into a connected ecosystem built by data, accuracy, and intelligence. At the core of this dramatic turning point lies the development of digital twins, which changes the way factories think, plan, and execute.

A digital twin imposes itself as the mind of a modern factory: a living, data-driven reflection of physical behavior. It allows manufacturers to simulate, predict, and optimize every aspect of production before making any physical changes. AI-enabled insights, data from IoT devices in real-time, and predictive analytics would help businesses predict problems; enhance efficiency; and speed up innovation at an unprecedented scale.

However, the real effect of digital twin technology is not merely to make reactive maintenance foresighted. Rather than responding to failures, factories now prevent them. Rather than relying on conjectures, they now rely on facts. Dynamic loops of ongoing improvement compose the organism wherein everything—goods, machines, processes, and decisions—results in growth measured in some fashion.

Being under the roof of limitless Industry 4.0, digital twins are fast losing that property of the future. To put it simply, the digital twin is the very foundation upon which manufacturing stands.

Esferasoft is bringing the future very close to reality with highly intelligent solutions in developing digital twins. We integrate AI, IoT, and data analytics to enable manufacturers to have the power to lower costs and enhance performance while differentiating themselves from competitors in a highly competitive marketplace.

The next generation factories will not only work with better efficiency but also think, adapt, and innovate. It has already started, and it has started with your digital twin.

FAQ’s

1. What is a digital twin in manufacturing?

A digital twin is a virtual model of a real-world machine, production process, or complete manufacturing plant. Data from IoT sensors and other connected devices is relayed to this twin, which lets manufacturers visualize, analyze, and simulate operations in real time.

This virtual twin helps address performance bottlenecks, predict when maintenance needs to be performed, and optimize production efficiencies—all without perturbing physical operations. Simply put, a digital twin grants manufacturers the sight and smarts within their systems to make faster, safer, and cheaper decisions.

2. How does a digital twin differ from simulation software?

Simulation applications use a static or preloaded data stream to assess “what-if” scenarios. Digital twins, on the other hand, are very much driven by real-time data, which itself evolves with the physical system.

- A simulation provides a snapshot.

- A digital twin provides an ongoing window into and vision of the future.

The very connectivity of the digital twin with the underlying reality through IoT and AI-powered analytics enables it to learn of changing conditions, detect anomalies, and make autonomous recommendations. It is like watching a film about your process instead of being present through a live, interactive dashboard predicting the next event.

3. What are the top benefits of using digital twins in manufacturing?

The advantages certainly go way beyond that of just savings. Digital twin technology ensures the establishment of a data-driven culture where every process can be monitored, optimized, and improved.

Some key benefits are:

- Predictive maintenance: “Failures” are detected before they happen so as to minimize unplanned downtimes.

- Improved production efficiency: Real-time insights lead to instant readjustment across the factory floor.

- Faster research and development cycles: Virtual prototyping is shortening product design and testing stages.

- Sustainability: Tracking and optimizing energy consumption, material waste, and resource use.

Hence, in the long run, it increases productivity and enhances operational resilience.

4. Which industries benefit most from digital twin technology?

While manufacturing may be the main industry availing of the digital twin technology, the solutions offered by this technology are changing many sectors.

- Aerospace and automotive are done for testing the performance of complex mechanical systems and optimizing systems.

- Energy and Utilities: Used for predictive maintenance of turbines, pipelines, and grids.

- Healthcare: Used for building patient-specific models, maintenance of equipment, and hospital operations.

- Construction and Infrastructure: For performance monitoring of large-scale construction projects and smart city systems.

- Logistics and Retail: For inventory monitoring, warehouse automation, and route optimization. Every industry updated its digital twin development according to their different data and performance needs to one main end—to enhance visibility, control, and intelligence.

5. How does IoT, AI and cloud computing add to the performance of digital twins?

Since IoT communicates with some intelligent cloud-based digital twin platforms, its integration makes it all the more a powerful research field in the world:

- IoT sensors acquire real-time data of the apparatus and environment and continue.

- AI and machine learning would analyze, forecast, and predict future outcomes with the pattern and anomaly detection.

- Use of cloud infrastructure makes the data processing scalable, remote, and real-time updated.

In other words, continuous learning takes place where dynamism exists, not only in the reflection of the digital twin of the physical world but also in the way the digital twin grows, making it a truly intelligent ecosystem.

6. What are the main challenges when adopting digital twins?

To put it mildly, here are some of the greater obstacles on the way.

- High capital costs for IoT infrastructure and analytic tools.

- Data integration issues resulting from attempts to bridge the gap between legacy and modern platforms.

- Cybersecurity risks posed by networks and clouds that are open for interconnection.

- Skill gaps in managing and interpreting data from Digital Twins.

Usually, organizations will pursue pilot projects with an idea of measurable ROI before scaling them up. Working with experienced partners like Esferasoft that provide digital twin development services is also helping in fast-tracking the process for the organizations while minimizing risk.

7. What tools or platforms are used in digital twin making?

Many different advanced tools and platforms are in use today for the development and management of digital twins. Some of these include:

- Siemens MindSphere Industrial IoT integration and analytics.

- PTC ThingWorx Real-time monitoring and predictive maintenance.

- Microsoft Azure Digital Twins Scalable cloud-based twin environment.

- IBM Digital Twin Exchange Asset lifecycle management and collaboration.

- ANSYS Twin Builder Physics-informed simulations integrated with live data at Esferasoft.

We would integrate such platforms into the ecosystem where the core is built digitally to include custom APIs, AI models, and IoT frameworks perfectly tailored to each client’s manufacturing needs.

8. How will digital twins influence the future of Industry 4.0 and smart manufacturing?

Digital twins rapidly evolve from monitoring tools toward autonomous decision systems. In the very near future, they will be used by manufacturers to run their entire operations virtually before making any physical changes.

Look for:

- Self-healing systems will automatically find faults and correct themselves.

- AI optimization that balances energy, output, and cost in real time.

- Complete lifecycle management from design through to recycling, all simulated within the twin.