|

Getting your Trinity Audio player ready...

|

Inventory management is a vital function that supports supply chain operations. The business environment of today requires real-time inventory visibility through RFID + AI for real-time inventory visibility because customers now demand better service and global supply chains have become more complex. The traditional methods of inventory management, which include manual stock checks and barcode scanning, no longer fulfill the requirements of modern inventory management in fast-paced environments.

RFID technology together with Artificial Intelligence (AI) produces two fundamental technological advancements that transform how businesses achieve inventory visibility. The combined power of these technologies enables supply chains to operate at greater efficiency while they reduce operational errors and provide necessary inventory data, which helps organizations retain their competitive edge.

The blog post explains how RFID and AI technologies create new methods for businesses to achieve real-time inventory tracking while describing the important factors that organizations must consider before deploying these technologies.

The Inventory Visibility Problem in Modern Supply Chains

The current supply chain system faces multiple obstacles, which include demand fluctuations, insufficient real-time tracking, incorrect inventory assessments, and productivity issues. The Supply Chain Insights study revealed that 43% of companies named their primary inventory management challenge as the lack of real-time inventory tracking capability.

The lack of visibility leads to stockouts, overstocking, and delays, resulting in financial losses, customer dissatisfaction, and issues with warehouse operations. The industry needs new RFID warehouse tracking systems instead of old ones that rely on manual inventory checks, because those manual checks don’t provide the necessary flexibility and accuracy for managing inventory.

Companies use AI and RFID technology to create real-time visibility, which enables them to enhance forecasting accuracy while reducing stockout incidents and bettering their decision-making processes.

what is RFID technology

The term “RFID” stands for Radio Frequency Identification, and it’s a technology that uses electromagnetic fields to automatically recognize and track tags linked to objects. Additionally, RFID tags incorporate a microchip that stores information, which an RFID reader can read through radio waves. Unlike traditional barcode scanning, RFID doesn’t need a direct line of sight to scan, making it perfect for large-scale operations where items need to be monitored from a distance.

Therefore, for smoother supply chain operations, AI-powered inventory management is used to track inventory across numerous stages of production, transportation, and, more importantly, storage. The technology boosts inventory accuracy, reduces manual labor, and offers real-time data for workflow optimization.

Role of Artificial Intelligence in Inventory Management

The inclusion of AI is transforming inventory management by providing powerful tools for data analysis, automation, and decision-making. Along with this, AI algorithms can process vast amounts of data collected from RFID sensors to detect patterns, predict demand, and optimize stock levels.

For instance, AI can easily assist in identifying trends in sales and alert supply chain managers about lower stock levels before they become critical and even streamline repetitive orders. Moreover, AI can be integrated with other business systems, such as ERP and WMS, to create a fully synced supply chain that operates smoothly and efficiently.

In addition to predictive analytics, AI-powered systems also leverage machine learning to regularly improve the overall accuracy of inventory tracking and demand forecasting over time.

Benefits of RFID Technology

The integration of an improved and exclusive RFID inventory management system brings many unique benefits; some of them are listed below:

| Benefits | Description |

| Boost Accuracy | The technology improves stock counting accuracy because RFID systems direct an automatic inventory counting procedure, which eliminates the errors of manual counting. |

| Real-time Tracking | RFID technology functions just like standard barcode systems, which provide ongoing tracking for inventory throughout its entire life cycle. |

| Labor Efficiency | RFID automation reduces the demand for manual checks, freeing up employees for more valuable tasks. |

| Minimized Shrinkage | With the help of RFID technology, enterprises can quickly identify missing items, reducing theft and misplacement. |

| Rapid Processing Rate | The RFID inventory tracking system eventually reduces the time it normally takes to check inventory in and out of storage, speeding up overall warehouse operations. |

How RFID and AI Work Together for Real-Time Visibility

The system uses RFID technology to provide real-time inventory tracking because it uses electromagnetic fields to identify and monitor objects through their attached RFID tags. The tags you referred to include a microchip, which stores data that the chip transmits to an RFID reader through radio frequency transmission. The system collects extensive data through RFID technology; however, AI changes that data into valuable business insights. The RFID data collection process gives AI systems the business intelligence they need to do their analysis.

AI enhances inventory accuracy by detecting discrepancies between actual RFID reader measurements and inventory management system records. The AI system informs managers about inventory issues that arise from incorrect stock levels and misplaced items. The inventory system maintains its current state because the process only needs one scanning task to check inventory while reducing chances of human mistakes.

The combination of RFID technology with AI enables businesses to create an intelligent inventory management solution that uses real-time tracking and analytical capabilities to continuously improve its operational performance.

The two systems function together because each system performs its designated tasks.

- Data Collection: RFID tracks inventory movement through the supply chain by providing continuous real-time data collection. The system enables tracking of items through their location, total count, and present condition without requiring operators to perform scanning duties.

- Data Analysis: The system employs machine learning algorithms to detect current patterns while it predicts future needs and determines the best inventory levels.

- Automation: The AI-powered inventory management system uses its AI-driven data to automate the process of restocking and redistributing products back to the warehouse. The system reduces the need for manual labor, which results in better operational productivity.

- Real-Time Decision-Making: The AI-powered insights enable businesses to make their decisions with greater speed and accuracy through real-time decision-making. AI systems employ real-time data to manage stock replenishment and pricing adjustments and shipment routing procedures.

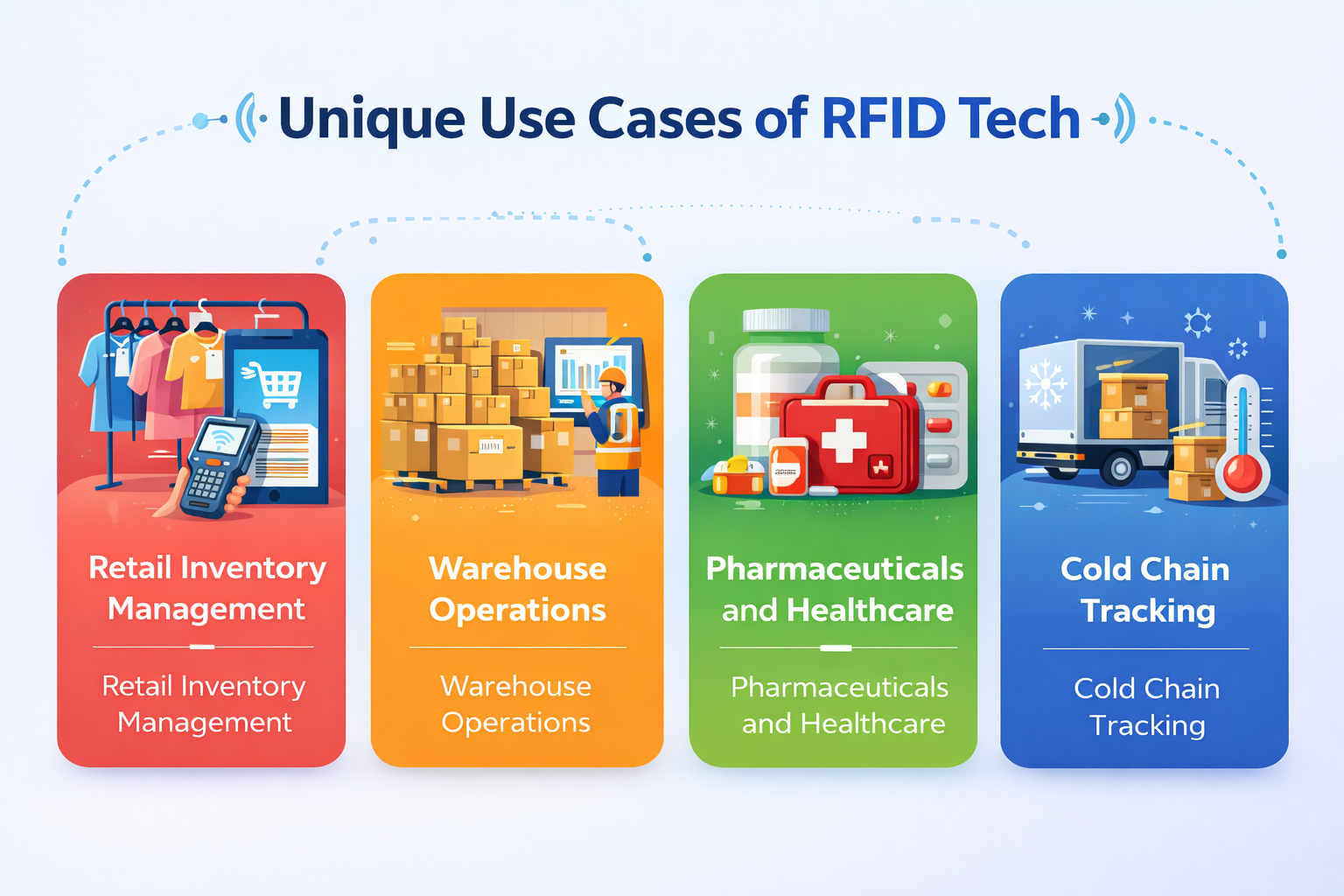

Unique Use Cases of RFID tech

Implementing RFID inventory management systems has a significant impact on various sectors, leading to unique use cases where RFID technology excels.

-

Retail Inventory Management

RFID tags enable retailers to maintain a real-time view of their stock, ensuring they never run out of popular items and can quickly identify slow-moving products.

-

Warehouse Operations

Another use case of RFID technology is that it helps track inventory in real-time as it moves through the warehouse, automating receiving, picking, packing, and shipping processes.

-

Pharmaceuticals and Healthcare

Through RFID, pharmaceutical companies can track medicines from production to delivery, ensuring better compliance with regulations and preventing counterfeit products from entering the market.

-

Cold Chain Tracking

RFID combined with AI can easily track temperature-sensitive goods such as food and medical equipment, guaranteeing they are stored and migrated under stable conditions.

System Architecture of RFID + AI Inventory Platform

The platform for inventory management which utilizes RFID and AI technologies, establishes ongoing connections between its various components to deliver real-time tracking and automated system functions and continuous performance enhancements. Every system component delivers vital support, which enables inventory management to achieve greater precision and faster processing times and maximum operational effectiveness.

- RFID Tags

- RFID Readers

- AI Engine and Analytics

- Inventory Management Software (IMS)

- Cloud-Based Infrastructure

- Automation Layer

- User Interface (UI)

So, we will discuss all these pointers one by one.

RFID Tags

The system’s initial framework requires RFID tags because they function as the core elements needed for its establishment. RFID tags use their built-in design to attach microchips and antennas to inventory items, pallets, and bins. Organizations can track items through the supply chain process because every RFID tag contains a unique identifier known as UID. The tags permit the storage of product names, batch numbers, location information, and additional data elements. The tags permit the storage of product name, batch number, and location information, and additional data elements.

RFID Readers

RFID readers function as devices that extract information from RFID tags through their data collection capabilities. The system requires readers to be installed at multiple points, which include warehouse entrances, conveyor belt systems, and shelf areas. The system uses radio wave technology to establish communication links with tags that deliver real-time information about product movement and environmental conditions. The RFID readers possess the capability to read multiple tags at once, while traditional barcode systems require users to perform line-of-sight scanning to read individual barcodes.

AI Engine and Analytics

The AI engine works as the core component of the RFID plus AI platform. The system extracts data from RFID readers to process it through advanced algorithms, which include machine learning, predictive analytics, and deep learning. AI enables businesses to use historical data analysis, pattern tracking, and demand forecasting to optimize their inventory levels, predict stockouts, and prevent overstocking. The AI engine uses real-time monitoring to detect anomalies through its identification of missing items and damaged goods.

Inventory Management Software (IMS)

The RFID reader system, together with the AI engine, collects and processes data, which the inventory management software uses for centralised data handling. Then, the software allows supply chain managers to use real-time inventory details displayed on the dashboard & reporting functions that show stock movements & vital performance indicators. Also, the IMS integrates with ERP, WMS, and TMS to boost efficiency and operational accuracy throughout the entire supply chain network.

Cloud-Based Infrastructure

The system uses cloud computing technology as its main foundational element for conducting data storage and processing operations. The cloud infrastructure enables businesses to access real-time data from any location, ensuring that supply chain teams can monitor inventory and make decisions on the go. Cloud solutions provide demand-based scaling capabilities, which enable businesses to combine new AI models with updated data streams for system enhancement.

Automation Layer

The RFID plus AI system connects with physical warehouse operations through its automation layer that functions as a connector between the two systems. AI-driven robots, drones, or automated guided vehicles (AGVs) use RFID data to execute their inventory picking, sorting, and packing tasks. The RFID inventory tracking system supplies real-time data to these devices, which use it to conduct their workflows without human assistance while achieving maximum operational effectiveness.

User Interface (UI)

Supply chain operators interact with the RFID plus AI system through the user interface, which serves as their dedicated access point. The system shows inventory status, alerts, forecasts, and performance metrics through the user interface. Managers can create their own dashboards, which enable them to explore particular data elements or obtain general operational data to assess and respond to active insights.

Implementation Challenges and Considerations

Real-time inventory visibility through RFID combined with AI technology provides numerous advantages while presenting particular challenges that must be resolved before successful implementation can occur. The following benefits of RFID and AI integration into inventory systems must be understood by businesses before they start implementing these technologies:

High Initial Investment

The main obstacle that prevents businesses from using RFID and AI systems arises from the requirement to pay substantial initial expenses. RFID technology implementation demands that organizations allocate significant financial resources because they must acquire RFID tags and readers and AI software. The business must calculate expenses for infrastructure upgrades, which include network bandwidth, server capabilities, and cloud storage requirements. Small businesses face significant challenges because they must pay upfront costs, which will deliver them future savings through improved operational efficiency.

Integration with Existing Systems

Organizations that continue to use legacy systems for their inventory management face difficulties when they need to implement new RFID and AI solutions. Organizations need to build custom systems that will enable their RFID data to work with their existing Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) systems. The systems need to operate together flawlessly while they exchange information constantly to prevent productivity loss and operational problems.

Data Privacy and Security

RFID systems track all inventory movement while they monitor stock quantities and product specifications. The data becomes extremely sensitive when it involves pharmaceutical products because their traceability must remain intact for safety and compliance reasons. We need to secure the data protection process for RFID tag data collection against known security threats. Organizations need to create robust data protection systems that will stop unauthorized access and data breaches while they comply with GDPR and HIPAA regulations.

Tagging and Reader Placement

RFID technology eliminates the need for line-of-sight scanning, but for the best results, RFID tags and readers must be placed correctly. Inventory items need proper attachment of inventory tags. which will enable readers to accurately read them, while readers must be situated at designated locations that provide access to all areas and barriers, including walls and shelves and heavy equipment. The system needs the correct tag and reader placement because incorrect placement leads to missed scans, inaccurate inventory data, and operational problems.

Training and Change Management

Businesses need to provide their workers appropriate training on new systems used to successfully implement RFID plus AI technology. Employees must acquire RFID reader operation skills together with AI insight comprehension and automation system usage training, as these skills will become essential for their job duties. Manual inventory organizations encounter challenges when they try to adopt new inventory control methods because their systems depend on traditional inventory processes. The organization requires training programs to support their change management activities and successful organization-wide transformation process.

Ongoing Maintenance and Support

The RFID and AI systems require ongoing operational assistance and continuous maintenance work to keep them running. The company needs to perform regular calibration of RFID readers and tags, while software updates should occur to include new system features and enhancements. The supply chain patterns, product demand fluctuations, and other changes require AI models to undergo ongoing retraining processes. After organizations complete the implementation stage, they must create a system maintenance budget and establish a support framework to address any issues that arise in their system.

Scalability

RFID + AI systems need to support business expansion because organizations will need to manage growing inventory levels and multiple locations while their operations become more complicated. The system faces two major challenges with scalability because it requires handling increased data storage needs and processing power requirements while keeping system performance intact when both RFID tag counts and data volume expand.

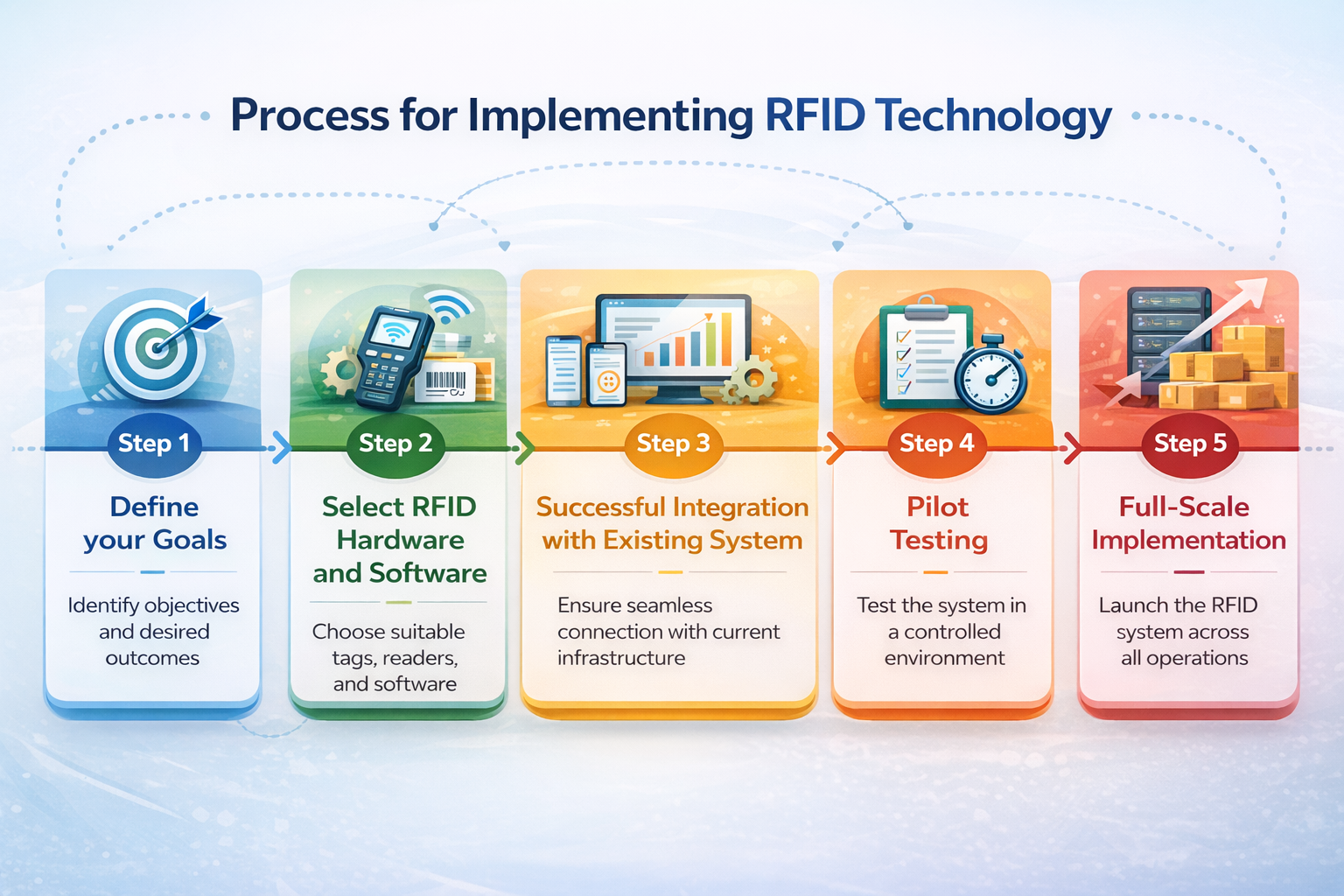

Process for Implementing RFID Technology

To implement the RFID technology in the system, you need to perform the following steps:

Step 1. Define your Goals

The first step requires you to determine your RFID and AI goals, which include improving inventory accuracy, decreasing stockouts, and automating warehouse operations.

Step 2. Select RFID Hardware and Software

In this step, you need to select RFID tags, readers, and, more importantly, software that will fulfill your business requirements.

Step 3. Successful integration with Existing System

Make sure your RFID and ai-powered systems operate appropriately with your existing ERP and WMS systems.

Step 4. Pilot Testing

The pilot test process establishes operational limits to which all subsequent testing will be conducted.

Step 5. Full-Scale Implementation

After completing the pilot successfully, you will execute system deployment throughout your entire supply chain network.

Future of Autonomous Warehouses and Smart Stores

Now comes the future of RFID and AI integration, headed toward 100% complete automation. Streamlined operations powered by RFID and AI technology will manage inventory from end to end in the autonomous warehouses. Therefore, with minimal human intervention, AI algorithms will automatically optimize stock levels, detect issues, and trigger replenishment while robots perform tasks such as picking, packing, and delivering.

In retail, smart stores will take help of RFID to offer customers endless shopping experiences. Also, RFID enables instant checkouts, personalized recommendations, and real-time inventory updates, making for a convenient shopping journey.

Why World Leaders trust Esferasoft for the Implementation of RFID technology

Esferasoft Solutions is the leading name in RFID and AI implementation in supply chain management. With years of excellence and expertise in leveraging these technologies into complex systems, our agency helps businesses automate their operations, reduce costs, and improve accuracy. World leaders in manufacturing, retail, and logistics trust Esferasoft Solutions. Also, Esferasoft delivers customized solutions tailored to the unique needs of every client.

Whether your goal is to enhance warehouse efficiency or obtain real-time visibility into your inventory, Esferasoft can help. Also, our team of experts ensures a smooth execution of RFID + AI systems.

Conclusion

RFID and AI technologies are transforming the way businesses manage their inventory. The combination of real-time visibility together with predictive analytics and automation tools enables companies to enhance their operational performance while cutting expenses and building their market advantage. The implementation of these technologies enables businesses to maintain their competitive advantage in supply chain operations, which are becoming increasingly complicated.

FAQs

Q1. What is real-time inventory visibility using RFID and AI?

The RFID + AI gives real-time inventory visibility of items, allowing businesses to check exactly where products are located and how much stock is available, and when it’s time to reorder, all in real time.

Q2. How does RFID improve inventory accuracy compared to barcode systems?

RFID improves operational speed and precise inventory tracking because it eliminates the requirement for direct visual contact, which barcodes need. The system uses RFID technology to collect multiple data points, which include tracking the whereabouts of items and monitoring their status, resulting in an all-inclusive inventory control system.

Q3. Can AI predict stock shortages using RFID data?

AI uses RFID data analysis to forecast stock shortages, which enables businesses to order new stock before they reach complete depletion.

Q4. Is RFID + AI suitable for small warehouses and retail stores?

The RFID plus AI system operates effectively for businesses of all sizes since its design permits companies to choose their operational scale. The system enables small businesses to achieve improved inventory accuracy through its continuous inventory management system, which also decreases their need for personnel resources.

Q5. What hardware is required to implement an RFID inventory tracking system?

The system requires RFID tags and readers plus antennas and software that operates the data management system. Your business needs specific hardware based on your operational scale requirements.

Q6. How does RFID + AI help reduce inventory shrinkage and theft?

The combination of RFID tags with AI technology establishes an effective system for preventing theft. The RFID system tracks all items in the supply chain and retail environment by providing real-time information about their current locations and movements. AI uses the gathered data to find suspicious activities that include items being taken out of the store without payment scanning, plus strange stockroom operations and inventory count errors.

Along with this, the system generates instant notifications The system alerts relevant personnel about any detected anomalies to ensure that emergency response teams can act promptly.way. The solution provides complete automated inventory tracking, which streamlines inventory assessments and marks locations where theft occurs most frequently and estimates future theft risks, while it decreases both internal and external inventory losses and enhances accuracy.

Q7. Can RFID inventory systems integrate with ERP and warehouse management software?

RFID systems enable data sharing between ERP systems and warehouse management software because they establish connections with these existing systems.

Q8. What is the implementation cost of RFID and AI inventory tracking solutions?

The company needs to evaluate the total expenses for the RFID and AI inventory tracking systems implementation. The expense for implementing RFID and AI inventory tracking systems needs to be determined through an evaluation process, which requires three primary aspects to be assessed. The business benefits from long-term financial savings through reduced labor costs and enhanced accuracy, which exceed the initial investment cost.