|

Getting your Trinity Audio player ready...

|

Smart factories redefine the future of manufacturing: automated, data-driven, and intelligent systems bring precision and unmatched efficiency to the future factories. At the heart of this transformational process lies Industrial AR Solutions, an important bridge between human expertise and digital intelligence. The hands-free active visualization capability is how this technology brings industries to work smarter, safer, and faster than ever before.

At Esferasoft, it is very much believed that Industrial Augmented Reality (AR) is far beyond just a mere tool—it’s an enabler of building connected and data-driven factories that are in line with the whole Industry 4.0 vision. Picture a technician putting on smart glasses and seeing a 3D overlay of machine parts, real-time metrics, and guided instructions without ever needing to open a manual. That’s how Industrial AR Software magically brings physical workspaces together with digital intelligence to optimize every production and maintenance stage.

The manner in which AR for Smart Factories is revolutionizing the working of teams in an increasingly competitive industrial terrain is being observed at present. Be it AR in production for assembly, maintenance, or inspection, companies are realizing the advantages of utilizing the technology with a substantial reduction in downtime, increased accuracy, and heightened levels of safety. The combination of industrial AR devices with IoT and AI systems allows workers to visualize performance data, diagnose problems early, and work directly with remote experts in real time—all within view of their workstation.

What AR brings to industry 4.0 is this humanizing aspect to the otherwise very technologically complex. AR does not replace people; it enhances them. It makes available contextual, visual, and interactive information so that the skill development—improved decision-making—can significantly provide a safer and more informed workforce. It is especially crucially important in potentially high-risk environments where predictive maintenance, real-time alerts, and guided troubleshooting can prevent serious costly errors or accidents.

As Esferasoft is continuously working to advance the AR manufacturing solution, we also aim at enabling enterprises to realize the full benefits of smart factory AR integration—from the ability to seamlessly flow production to intelligent asset management. Those systems connecting to one another out there will be future-telling things, but now they could reshape industrial efficacy and sustainability.

This blog will take us through how Industrial AR Solutions are transforming manufacturing into great practices and real applications and paving the way for predictive, connected, and sustainable industrial ecosystems in this digital transformation age.

What is meant by Industrial Augmented Reality?

Industrial Augmented Reality (IAR) is redefining factories by creating a precision, digitally driven system combined with the agility of human intelligence. IAR connects the physical world with the virtual world so that it can make real-time, data-driven insights improve productivity and safety and facilitate better decision-making within a factory.

Below is a deeper look at how Industrial AR Solutions function and why they’re reshaping the future of smart manufacturing.

Industrial Augmented Reality Definition

Specifically, it is the application of augmented reality in the context of industrial environments, including factories, warehouses, and maintenance buildings. Where AR for consumers is oriented toward entertainment or retail, Industrial AR is designed for function rather than for accuracy. Industrial AR uses such devices as smart glasses, tablets, or headsets to digitally overlay 3-D models, instructions, alerts, and analytics on top of real machines or processes.

This integration allows working with both the physical asset and its current digital twin without interrupting the work rhythm. For example, an operator just points a tablet at a machine and immediately sees live performance data, or a technician wearing AR glasses is guided through repair steps without manual reference.

Industrial AR Working

Industrial AR Solutions provide connecting links between IoT sensors, machine vision, artificial intelligence, and industrial AR software under one umbrella, from which all data are collected from connected equipment and visualized within the worker’s field of view:

- Data Collection: Machines and sensors collect real-time data, for example temperature, vibration or performance rates.

- Integration: Relay of the data onto the AR platform using industrial networks or IoT gateways.

- Display: Down the AR device digital content, for instance, component diagrams or safety alerts, is overlaid onto the physical equipment.

- Interaction: Workers are interacting with those visual cues hands-free, using gestures, voice commands, or gaze tracking.

Creating that dynamic workspace to make decisions in real-time much quicker, with fewer errors, and make operations more transparent and efficient.

Applications for All Manufacturing and Maintenance

Industrial Augmented Reality promises applications across broad domains within manufacturing:

- Production and Assembly: The foundation aims to enable workers with interactive 3D assembly instructions to minimize errors and speed up production with the help of augmented reality information.

- Maintenance and Inspection: Real-time guidance is provided through augmented reality for technicians to detect faults and also for repair records.

- Quality Control: Operators using augmented reality in quality inspection can align design templates with finished products and identify inconsistencies.

- Training and Empowering Workforce: Simulating physical equipment in AR can equip a new hire on how to train in intense immersive simulations, thus reducing the amount of time taken for orientation.

These applications and the contributions of AR ideally recommend industrial integration by most companies with quality, consistency, and safety requirements in the most challenging environments.

Why Industrial AR Matters in Smart Factories

In the Industry 4.0 era, the connection of machines, data, and people is the major subject of research in industrial sectors. The industrial AR has a significant role in facilitating this mission because it gives real-time information to the point of action. The reality creates visual insights, which are supposed to empower the teams to decide proactively.

Factories today can capitalize on their application by using an AR feature in both production and maintenance to reduce downtime, boost asset longevity, and improve workforce usage—all without losing operational safety and compliance. Further, AR in Industry 4.0 augments direct human-machine collaboration while permitting people to work more confidently with robotics and automation systems.

Esferasoft’s Approach to Industrial AR

Esferasoft is in charge of designing and developing the tailored industrial AR software for the clients in manufacturing, logistics, and maintenance operations. It builds a seamless integration with existing IoT, ERP, and digital twin infrastructures, thereby ushering enterprises into data-driven smart environments. Be it predictive maintenance AR or real-time inspection and training applications, we strive to make businesses more efficient in the reduction of operational risks.

The Importance of Industrial Augmented Reality in the Era of Industry 4.0

The fourth industrial revolution, or Industry 4.0, is creating paradigms for how factories will operate. Machines, data, and people are interconnected for the first time, creating ecosystems with perception, cognition, and real-time action. This is the way in which the intelligent ecosystem blends industrial AR solutions and humans with cognitive skills in order to empower them in mapping their physical environments with virtual ones for a transformative management of disruptive innovations of production and maintenance and training processes.

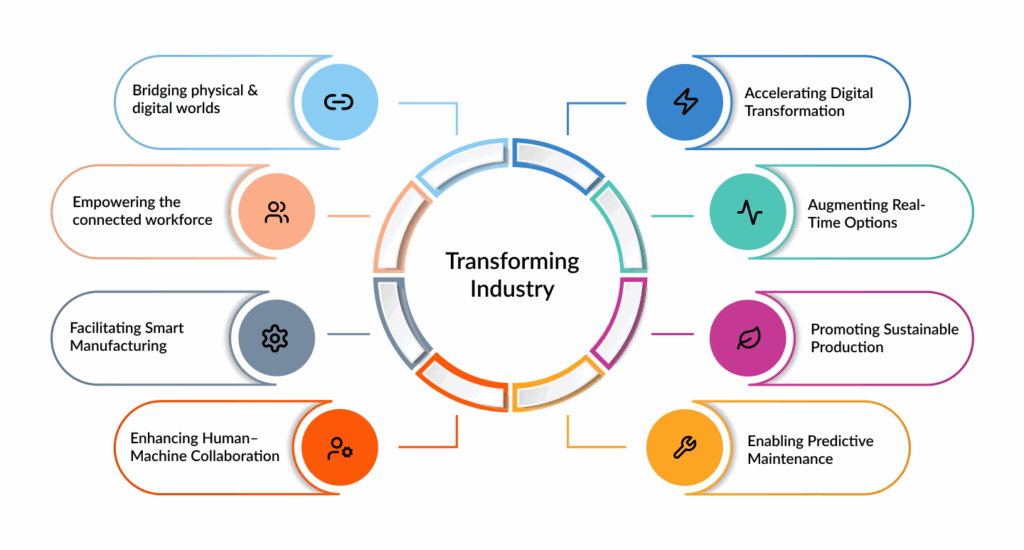

Bridging the Gap between the Physical and Digital Worlds

At the heart of AR in Industry 4.0 is its ability to link physical assets with their digital twins. This can combine AR devices to become internet-enabled for IoT sensors, robotics, and digital twins for gaining real-time visibility into any aspect of production. A maintenance engineer, for instance, can use industrial AR devices to visualize internal machine components, determine performance issues, and initiate repairs, all without opening the machines.

This results in reduced downtime and enhanced accuracy in a seamless digital ecosystem, where the interaction between humans and machines is quite instinctive and efficient.

Empowering the Connected Workforce

In a smart factory, industrial AR technology empowers the workforce by turning data into actionable insights. They don’t have to rely on manuals, printed copies, or dashboards filled with static images; they’re able to see step-by-step visual guides right in front of their faces. For this, a wonderful example is remote support through AR manufacturing solutions, by which specialists do have the opportunity to reach out to their field teams for live troubleshooting and knowledge transfer.

Thus, the connected workforce, which is more agile, knowledgeable, and confident in solving complex challenges facing industries, is created instead of the traditional workforce.

Facilitating Smart Manufacturing

Through visualizing complex processes through simple and interactive means, Industrial AR Solutions enhance the precision and speed of manufacturing operations. In AR-supported production and assembly, workers receive real-time instruction visualized at the workstation, considerably decreasing error rates and improving turnaround time.

In this way, it works hand-in-hand with lean manufacturing, thereby promoting large-scale value-adding activities that ultimately work toward higher-quality output that is paramount to factories targeting zero defects.

Enhancing Human–Machine Collaboration

In the modern factories, a mix between automation and human intelligence is what keeps the machine running. The AR helps in developing that relationship in industrial applications by providing a common interface where people and machines share information effortlessly. Machine operators, for instance, may monitor the operation of robots via AR dashboards and make real-time adjustments while also visualizing safety zones whenever necessary.

This interface increases situational awareness, enhances safety, and maximizes productivity but never at the expense of the workers’ interest.

Accelerating Digital Transformation

Digital transformation is not about the adoption of technologies but the reimagination of processes. It is the key point in such a transition, allowing digital data to be available to all, from technicians to management. It also makes it much easier for Industry 4.0 technologies, such as IoT, AI, or digital twins, to be adopted with a simple visual interface that anyone can comprehend.

At Esferasoft, we help organizations implement Industrial AR at scale to allow seamless integration with measurable ROI.

Augmenting Real-Time Options

One of the utmost advantages of Industrial AR technology is offering access to live contextual data. Through AR, overlays allow operators to be updated on what is happening and, most importantly, why. The result could be changes in temperature and the visualization of performance metrics—both enhancing the speed and accuracy of decision-making.

Agility is particularly useful for environments where production is a race against time; every second counts.

Promoting Sustainable Production

Being sustainable itself is a pillar of Industry 4.0, and AR in smart factories is there to decrease material wastage, enhance energy consumption, and amplify maintenance efficiency. AR for predictive maintenance may arguably be one of the best methodologies to identify issues with equipment early on and avoid costly breakdowns and unnecessary replacements.

With sustainability goals having been set as global priorities, Industrial AR Solutions allow companies to build smarter, greener, and more resource-efficient operations.

Enabling Predictive Maintenance

Industrial AR and AI predictive maintenance are changing the paradigm of how factories maintain equipment. Workers can visualize real-time machine health data, receive alerts on possible failures, and follow visual repair instructions. Hence, this approach lessens unplanned outages, increases asset life, and lowers maintenance costs.

Ultimately, Industrial AR is much more than a passing trend in the context of Industry 4.0; it becomes a tactical enabler of people and process optimization and persists in the interest of sustainable innovation. As industries still evolve, AR will become the pillar for connected, intelligent, and resilient smart factories. To learn more, contact us at +91 772-3000-038!

Augmented Reality in Industry: What are the Uses of It?

Augmented Reality (AR) is an innovative technology that has cut across all industrial arms, making real-time data blend with what exists at that time in the physical environment. From design to maintenance, this solution enhances accuracy, thereby reducing downtime and improving the workforce performance—factories indeed have become smarter and more connected.

Connected Product Design and Development

Industrial Augmented Reality gives teams the opportunity to assess 3D with the real environment views before producing or launching the product. With augmented reality, engineers can walk around a virtual prototype and measure it instantly, including ergonomics. It minimizes rework, reduces design cycle time, and lowers costs.

Industrial AR Software by Esferasoft connects CAD and digital twin systems for real-time collaboration among engineers and designers all around the world.

Operations, Maintenance, Safety

AR is changing routine complicated maintenance duties to perform them. A technician scans the device, repairs its overlays, accesses live sensor data, and sees alerts on predictive maintenance—all done hands-free.

Moreover, their usage increases safety standards because these danger zones and warnings are real-time system alarms through AR for Smart Factories, making operations much safer and more efficient.

Training Employees and Operators

Commercialized Industry AR Training Solutions represent manual instructions through a mock-up rendition of the actual world. Through interactive 3D overlays of assembly steps, controls, and safety checks, trainees will learn.

Esferasoft’s AR learning modules can be mediated to get people up to speed. Still holding the potential to master the skills for the expected targets, even for a learner with a weak background, it will lessen errors.

Quality Control

With AR, quality inspectors could simply use the augmented reality object to superimpose their digital templates over physical products to instantaneously detect deviations. Such visual precision magnifies consistency in its products while at the same time minimizing inspection time.

Integrated with AI and machine vision, Esferasoft provides the Manufacturing lines with faster, more accurate, and traceable quality assurance via AR tools.

Essential Roles and Impact of Industrial AR Solutions in Smart Factories

Industrial AR Solutions redefine modern manufacturing paradigms as core enablers of smarter, safer factory ecosystems at their very foundation rather than being technological add-ons. They merge real-world environments with digital data, streamlining and driving down complex processes, downtime, and the precision at which company workforces must operate.

From the above, the key roles and inclusions of Industrial AR that make them key in today’s smart factories are outlined below.

Improved Training and Competency Development

Hands-on and experiential learning will make employee upskilling faster with AR training, as opposed to using manuals for reading. Using 3D instructions projected onto actual equipment will expose employees to hands-on learning as they learn how to do it. This method will improve retention, reduce training time, and minimize expensive errors.

At Esferasoft, we have Industrial AR Training Solutions to introduce standardized skill enhancement, making technical training more hands-on and scalable.

Real-Time Instructions and Assistance

By this technology, technicians and operators will receive live, step-by-step instructions while performing maintenance or assembly operations. Such smart glasses or tablets allow them to access diagrams, alerts, and performance data in real time. This kind of immediate feedback enhances accuracy and reduces reliance on the supervisor or printed manuals.

Simple Maintenance and Repair

Machine condition monitoring supported by the AR will forecast and guide maintenance, shutting out defective parts and suggesting repairs even before an impending machinery failure. This means reduced downtime and maximized equipment life.

A technician may also be able to contact external experts for live visual assistance using Industrial AR devices, solving issues much faster and without interrupting business.

Improved Quality Control

With AR, as concerned with quality control, it is now possible to detect improper conditions immediately by superimposing digital templates or CAD models on real physical products. This visual accuracy ensures that each corresponding element complies with design and safety standards.

Further achieved with artificial intelligence-driven analytics, inspection processes are automated with the Esferasoft AR solutions such that consistency and minimization of human error are brought about.

Remote Collaboration and Learning

Smart Factories make use of AR in providing remote repair and maintenance services by linking hardworking on-site personnel to experts from different parts of the world. The experts may be able to follow up on repair or inspection through real-time video and 3D annotations without traveling, thus saving time and cost and guaranteeing operational continuity.

Improved Efficiency and Production

AR eliminates guesswork involved in complex workflows. Within Man-AR Manufacturing Solutions, efforts that take hours can be reduced to minutes using visual clues, metrics, and optimized routes for both assembly and maintenance functions. This translates into a greater output with fewer errors and increased productivity even on its own.

Safer Operations

Safety is one mainstream advantage of Industrial AR Implementation. AR systems can show hazard zones or operating limits or emergency protocols to workers and keep them updated about the risks while safely operating the equipment with both hands.

Efficient Warehouse Management

In logistics and warehouse settings, AR under Industry Applications assists mostly in inventory picking, navigation, and placement of equipment. Workers get a view of where to find items while being routed along an optimized route, spending minimal time searching for or mishandling material.

The Industrial AR Solutions, put simply, will change the way smart factories operate by bringing together data, human skills, and mechanized systems into one coherent environment. At Esferasoft, we help transform enterprise implementation of these tools to measure gains in productivity, quality, and safety across all layers of industrial performance.

Emerging & Future Trends in Industrial AR

The evolution of Industrial AR Solutions is witnessing an accelerating pace thanks to advances in AI, IoT, and connectivity. These new innovations have begun to transform AR from a mere supporting tool into the strategic fulcrum of Industry 4.0 and even Industry 5.0, wherein human-machine collaboration reaches newer heights.

These trends are the few very significant in propelling the far future of Industrial Augmented Reality.

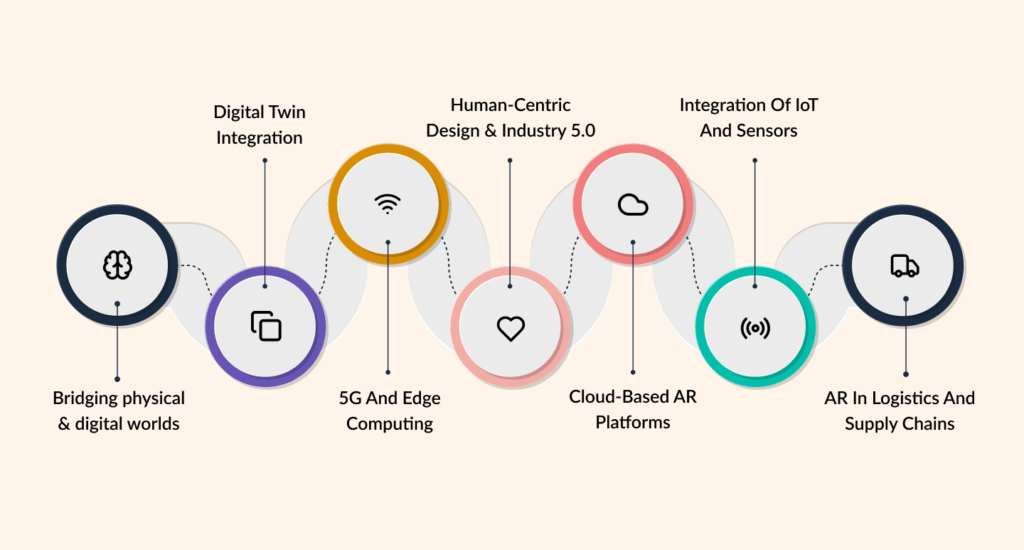

AI-Enabled AR Systems

Artificial intelligence contributes to AR by providing real-time object recognition, anomaly detection and automated decision support. The recent AI-propelled Industrial AR Software is capable of predicting equipment failure, assisting maintenance, and customizing training modules depending on the user performance.

Digital Twin Integration

The linkage of AR and digital twin provides an interactive simulation of structures in the real world. Operators can visualize machine health, test a process change, and predict results before taking action which allows for more mindful and safer industrial operation.

5G and Edge Computing for Real-Time Performance

5G and edge computer give faster, more secure transmission of data that leads to a seamless AR experience with little lag. This is crucial in real-time monitoring, remote collaboration, and quick maintenance update on the factory floor.

Human-Centric Design And Industry 5.0

The upcoming industrial phase revolves around human–machine collaboration. The main differentiators for AR in Industry 5.0 are the intuitive and ergonomic interfaces that augment safety and comfort and enable seamless collaboration between humans and intelligent systems.

Cloud-Based AR Platforms

Cloud connectivity allows shared AR environments to be accessed by global teams from any corner of the globe. Such capabilities are important for remote maintenance, design collaborations, and scalable deployments across a multi-site industrial operation.

Integration of IoT and Sensors

The IoT-enabled AR enhances the data from the sensors with 3D visualizations for the workers to get real-time updates. Thus, knowing the status of the machines and energy use in production flow, one can also facilitate predictive maintenance and improvements in efficiency.

AR in Logistics and Supply Chains

AR further causes more organizational work through improving the speed and accuracy of operations in logistics from warehouse picking to fleet tracking. The augmented reality system provides the employees with live visual overlay guidance about item locations or shipping details.

Intelligent integration is the name of the future in Industrial AR Technology, hence referring to the seamless fusion of artificial intelligence, the internet of things, and data analytics into immersive, connected ecosystems. In the next few years, Esferasoft is busy fitting Augmented Reality devices, which scale with size and capability. Consequently, it will provide a great boost in human efficiency and job security. For more information, call us at +91 772-3000-038!

Adverse effects of Industrial AR Solutions.

Industrial AR Solutions produce measurable results in all areas of manufacturing, including logistics and maintenance operations, worldwide. They equip companies to gain benefits beyond improved efficiency, such as real-time data blended with hands-on processes, which change the rules in an industrial ecosystem.

This is how Industrial Augmented Reality touches smart factories:

Less Downtime

Using AR for Predictive Maintenance, technicians can forecast and repair problems before they become breakdowns. Equipment downtime is reduced and production flows smoothly with real-time diagnostics and transportable visual repair instructions.

Enhanced, Improved Training Results

Training through Industrial AR Solutions hastens the delivery of skills between engaging modalities, making it easily absorbed by employees, resulting in reduced training time and high accuracy on the job.

Real-Time Safety Regulation

AR for Smart Factories develops a situational awareness regarding hazard alerts, operational limits, and safety protocols above real time. That has left workers informed regarding the prospective risks of their actions while performing most tasks with safety and efficiency.

Better Decision-Making

Develops through visualization of live data within the worker’s view. The supervisor may now evaluate productivity metrics, manage workflows, and adjust immediately, based on data-driven insights.

Increased Operational Efficacy

Linking AR in Production and Assembly with companion connected systems provides some of the most simple factories to simplistically complex workflows, reduces human error, and boosts output productivity; every task becomes faster and more uniform, resulting in sizable, measurable output gains.

Savings and ROI

Investment in the Industrial AR Software relates to maintenance and quality control, as well as logistics that have been reduced in labor costs and downtimes as well as wastes. The improvements pay high dividends over time, which contributes to industry-strength competitive advantages in the Industry 4.0 era.

Simply put, the reach of Industrial AR Technology will stretch beyond visual assistance. It is transforming how factories train, maintain, and manufacture: empowering human talent with digital intelligence.

At Esferasoft, we help enterprises tap into these increments through scalable, results-driven AR implementations aligned with technology with measurable business outcomes.

Challenges and Barriers to Adopting Industrial AR Solutions

Despite having transformed the phenomenon of smart factories, Industrial AR Solutions come with practical, financial, and organizational difficulties. An understanding of these barriers is critical in developing sustainable and scalable strategies for AR.

Financial & Resource Barriers

Setup costs continue to be one of the major concerns. Choosing to go in for Industrial AR Devices, their software licenses, and the related infrastructure installation is costly and thus proves forbidding for mid-scale manufacturers. Besides, many companies are still not sure whether it will yield profits or not.

Lack of Skilled Workforce

Industrial Augmented Reality brings a need for the technical and operational aspect of competence. Often the shortfall of AR developers, data engineers, and trained technicians slow down the process of integration and scaling.

Technical & Infrastructure Limitations

Modern AR technologies require high-speed connectivity, powerful computing resources, and smooth integration with IoT. Factories having outdated networks and data pipelines suffer from performance and accuracy issues regarding the AR visualizations.

Hardware & Devices Challenges

Smart glasses, tablets, and portable AR headsets are still in evolution. Battery duration, field durability, and comfort remain holding factors in heavy industrial environments.

Organizational & Cultural Resistance

Sometimes the workers hesitate to adopt new hardware or software because they are not familiar with it or maybe because of their fear about automating their job. In the absence of adequate change management, AR in Industry 4.0 projects runs a risk of avoiding engagement and success.

Data Privacy & Security Concerns

AR in industrial environments becomes a very delicate issue when different devices and networks share real-time data. It locks sensitive production or customer information without a strong encryption and a cybersecurity framework.

Thus, what corporations need is a clear-cut roadmap—including employee training, safe data infrastructure, and gradual implementation.

At Esferasoft, we assist businesses in the strategic adaptation of Industrial AR Technology-integration, performance, and long-term scalability of the implementation are assured.

Merged realities for the industrial world: industrial Augmented Reality

There are numerous varieties of Industrial Augmented Reality, depending on factories and workflow. From portable configurations to advanced wearables, these differences define how Industrial AR Solutions apply within maintenance and assembly, as well as quality operations.

1. Tablet/Smartphone-based AR

The most basic form of industrial augmented reality, this approach simply uses mobile devices to create virtual overlays on machinery or workspaces.

Technicians can scan equipment and instantly look at the repair guides, part numbers, or live analytics on their screens. Best for inspection, training, and quick maintenance without using dedicated hardware equipment.

2. Projection-Based AR

Instead, projection-based AR projects visual data onto real surfaces, for example, assembly benches or components. It’s a hands-free method that increases accuracy while performing production and assembly tasks by directing with visual cues, such as outlines or alignment indicators, improving speed as well as diminishing human error.

3. Wearable AR Devices

These include smart glasses or a head-mounted display, and they deliver real-time data into the operator’s field of vision. These systems are excellent for keeping users informed about real-time events in addition to getting assistance when troubleshooting, thus relieving the time spent on maintenance inspection and also doing a lot of training for maintenance activities performed by those users entirely hands-free.

Each of these technologies plays a different role in AR Manufacturing Solutions since they are flexible in terms of use case, cost, and environment.

At Esferasoft, our value proposition is to assist enterprises in selecting and deploying the most effective Industrial AR Implementation aligned with their technology with operational goals, workforce capability, and ROI potential. To learn more, contact our experts today at +91 772-3000-038!

Conclusion—Building a Smarter Future with Industrial AR Solutions with New Possibilities

Industrial AR Solutions are a transformative technology when it comes to smart factory processes. Organization has taken workforce marketing to new levels; efficiency, effectiveness, and safety have been achieved just with bringing together all the management components with data, automation, and human intelligence.

Augmented reality offers predictive maintenance and quality management. Industrial augmented reality empowers organizations to improve accuracy, efficiency, and safety. It delivers insightful information, hands-free direction, and by-the-moment localization with stronger decision-making power.

Esferasoft sees Industrial AR Technology as a new stream of opportunity, not merely a new technology. We visualize it as the foundation of the next generation of Industry 4.0. What we seek to offer our clients is the means to make their businesses adapt their current-day operations into the production of scalable AR Manufacturing Solutions while preparing them for the connected, human-centric factories of the future.

The future of manufacturing will be owned by those who advance the best mix of accuracy and intelligence. Industrial AR will be the way to create that intelligent, rapid, and resilient future.

FAQ’s

1. What are Industrial AR Solutions?

Industrial augmented reality (AR) solutions refer to proprietary augmenting tools of manufacturing processes by applying digital information such as 3D instructions, maintenance, and analytical data, for example, on duty with the workers, thus improving their task performance speed, safety, and accuracy.

2. How does augmented reality benefit smart factories?

It enhances efficiency at every level of operational productivity, namely, reducing downtimes, improving control of product quality, and the acceleration of training. It includes real-time visualization of data, guided maintenance, and hands-free cooperation of teams with experts, whether they are both on site or not.

3. Which are the Industrial AR Solutions best suited for use services?

Industries such as automotive, aerospace, electronics, logistics, and heavy manufacturing are the ones that profit most from it. Efficient assembly, accurate predictive maintenance, and the most effective inspection are common in all of these industries.

4. How does Industrial AR Benefit Industry 4.0 Objectives?

In Industry 4.0 applications, AR connects physical machines to digital systems. It enables connected operations, real-time analytics, and ultimately human-machine collaboration—all prerequisites for automation and data-driven production.

5. Adoption challenges of industrial AR?

Corporate AR adoption is faced with several hurdles, including pricing issues, the scarcity of a skilled workforce, infrastructural limitations, and security concerns regarding data. However, strategic planning and phased implementation could overcome these hurdles.

6. What role does augmented reality play in workforce training?

Industrial augmented reality (AR) training solutions offer immersive, simulation-based learning opportunities. In this way, workers can practice their assembly or maintenance work in a fully virtual environment, thus enhancing skill retention and minimizing errors when they are put down on the shop floor.

7. How does augmented reality differ from virtual reality in industrial applications?

While augmented reality superimposes digital information onto real environments, virtual reality creates an entirely synthesized one. AR is useful in settings such as live production and maintenance, whereas VR is more applicable to training and design visualization.

8. What does the future hold for manufacturing and Industrial AR?

The integration of AI-augmented reality application with IoT and digital twins has certainly defined the future of predictive, autonomous, and human-centric factories into a real-time and continuously collaborative environment.

9. Are Industrial AR Solutions compatible with IoT and ERPs?

Industrial AR software today does integrate well with IoT sensors, ERP platforms, and digital twins, and live performance data may easily be displayed, as well as simple automation of workflows on the shop floor.

10. How do companies begin to implement Industrial AR Solutions?

Start with a well-defined use case—whether it be maintenance, training, or quality inspection—and pilot on a small scale. Esferasoft helps organizations with the end-to-end implementation of Industrial AR from strategy and software development to systems integration and scalability planning.